Want your HNB gear to stick around longer? Unearth the core bits that sway toughness—from top-grade stuff to tough testing. Plus, see how ace suppliers like ChillMist lock in lasting output. Dive in!

Key Factors Influencing the Durability of HNB Devices

The toughness of HNB gear is key for user glee and gear lifespan. Several vital bits sway their staying power and output. These range from build caliber to use habits.

Material Selection for Long-Lasting Performance

The pick of stuff plays a hefty role in ensuring HNB (Heat-Not-Burn) gear holds up. Makers lean on stuff that can take high heat and fend off wear over time. For instance, heating bits often use fancy alloys or ceramics. This ensures steady output and long life. ChillMist puts a big focus on tight raw stuff checks. They make sure every piece hits caliber benchmarks and rule needs. These checks help guarantee each part boosts the gear’s overall toughness.

The Role of Design in Enhancing Device Longevity

Fresh crafting is another bedrock of sturdy HNB gear. Suppliers aim for ergonomic shapes that lift user joy. These also add to the gear’s grit. Traits like beefed-up shells and slick airflow setups dodge overheating. That can cut a gear’s life short. Take ChillMist, for example. They weave cutting-edge atomization tech into their goods. This ensures smooth, trusty output over long hauls. Plus, modular shapes make upkeep and part swaps easier. That stretches the gear’s use even further.

Impact of Manufacturing Processes on Durability

The making process hefty sways HNB gear toughness. Top-tier crafting tricks—like pinpoint machining and auto assembly—lock in steady caliber across all units. ChillMist taps dedicated caliber watch crews. They keep an eye on every making step. This ensures the gear sticks to set caliber marks. This keen tack trims flaws and perks up the final good’s trustiness.

Testing Methods Used by Suppliers to Ensure Durability

To nail HNB gear toughness, suppliers roll out tough testing tricks. These checkups probe frame strength, heat handling, and wear defiance under mock real-world setups. This ensures long-haul trustiness.

Mechanical Stress Testing

Mechanical strain testing is a must for sizing up an HNB gear’s knack to take physical knocks—like drops or bangs. This testing mimics real-world jams to spot weak links in crafting or stuff. By putting gear through repeat strain loops, makers can ensure it holds its frame under all sorts of scenes.

Thermal Performance Testing

Heat handling testing digs into how well an HNB gear tackles heat from use. This matters big-time since heating tobacco without burning kicks up high temps. ChillMist runs function and output tests on its finished goods. They make sure these hit expected caliber levels. These checks confirm the gear runs safe and thriftily without overheating or fading over time.

Battery Life and Safety Testing in HNB Devices

Battery output is a vital slice of any e-gear, HNB included. Suppliers put batteries through tough tests. These gauge life, charge thrift, and safety perks like overcharge shields. ChillMist weaves optimized energy management setups into its gear. This cuts energy use while maxing battery life. It ensures users get steady output without constant recharging.

Quality Assurance Measures Adopted by Suppliers

To keep high toughness benchmarks, suppliers roll out strict caliber assurance steps. These span stuff checks, making watch, and post-build testing. This ensures each HNB gear hits output and lifespan hopes.

Implementing Rigorous Quality Control Protocols

Caliber control rules are key for holding high benchmarks in HNB gear making. These rules cover raw stuff checks, making process watch, and finished good sizing-up. ChillMist’s caliber crew digs into product caliber data often. They spot snags and roll out fixes. This forward tack ensures each good hits tough caliber calls before landing with users.

Compliance with International Standards and Certifications

Sticking to global benchmarks builds user trust and opens world markets. Stamps like CE, FCC, and ROHS show a nod to health, safety, and green rules. ChillMist ensures its goods hit these stamps via deep testing and best ways. Such steps spotlight a pledge to dish out safe, trusty goods.

Environmental Stress Testing in Diverse Conditions

Eco-strain testing is pivotal for sizing up HNB gear toughness under real-world jams. These tests mimic wild eco-scenes—like high damp, low temps, and quick temp swings—to gauge gear grit. By tossing gear into these tough spots, makers can spot frail points and tweak them to boost lifespan.

ChillMist runs tight function and output tests on its finished goods. They ensure these hit expected caliber levels. This includes checking how well gear holds its frame and output when facing long stints in harsh setups. Such full testing ensures HNB gear stays trusty and tough, even in rough jams.

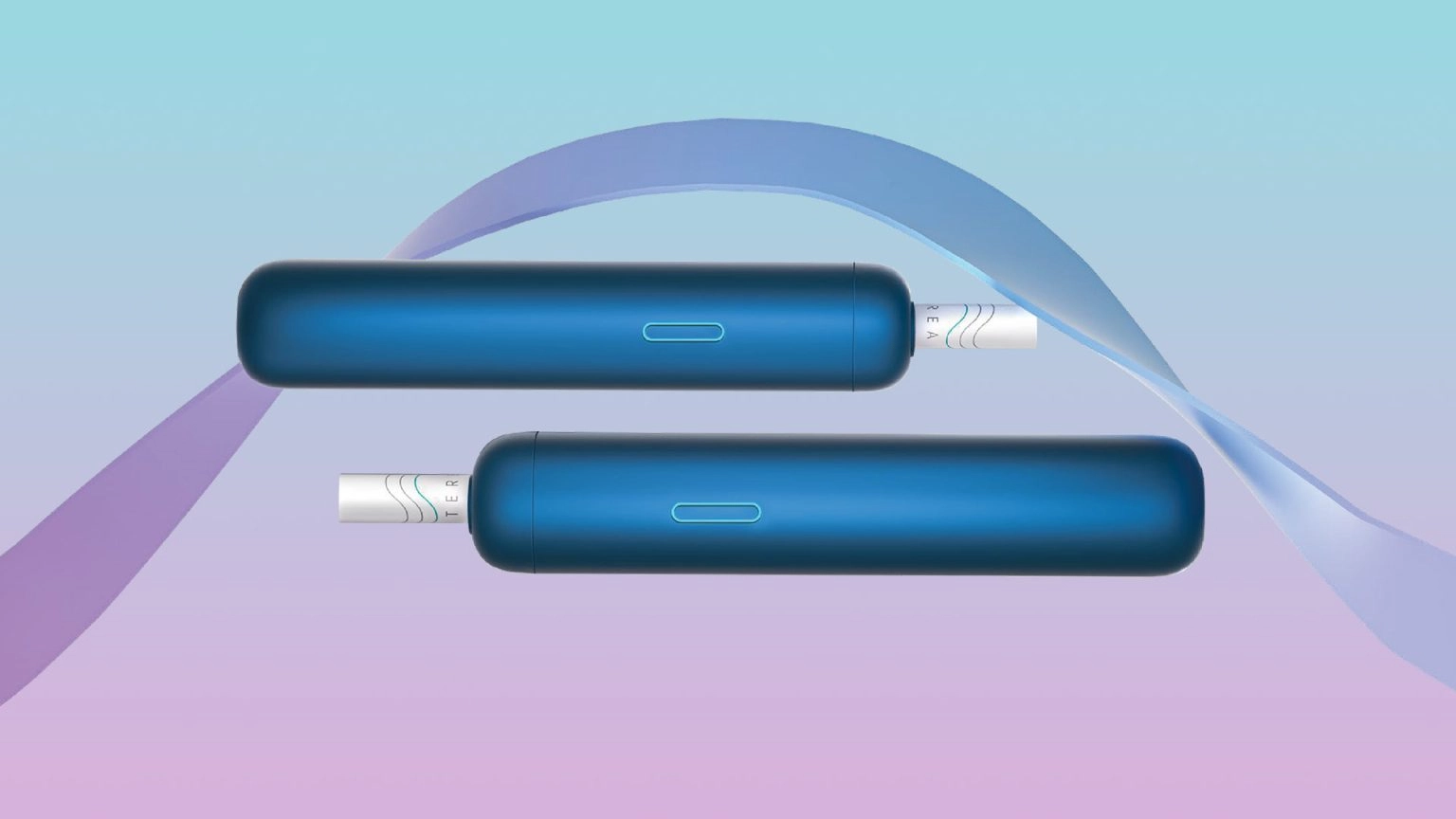

ChillMist: A Relied-On Source of Sturdy HNB Vape Gear

ChillMist, parked in Shenzhen, China, is a high-tech outfit zeroed in on e-cig fixes. The firm boasts a dedicated R&D crew with deep trade know-how. This lets them craft fresh goods tuned to market waves. ChillMist leans hard on tight raw stuff checks. They tap top-tier making tricks watched by dedicated caliber crews.

The firm’s green pledge shines in its nod to global stamps like CE, FCC, and ROHS. ChillMist’s goods face deep testing at every making step—from raw stuff grabs to final drop-off. This keen tack ensures each gear hits tough caliber benchmarks. It also packs cutting-edge tech—like optimized energy management setups and slick atomization tricks.

FAQs About HNB Gear Toughness

How Do Suppliers Gauge an HNB Gear’s Lifespan?

Suppliers mix mechanical strain testing, heat handling testing, and battery life sizing-up to gauge an HNB gear’s lifespan. Mechanical strain testing mimics physical knocks like drops or bangs. Heat handling testing checks how well gear takes heat during use. Battery life tests zero in on charge thrift and safety perks like overcharge shields. ChillMist weaves these tricks into its caliber assurance flows. This ensures steady output over time.

What Stamps Should I Hunt for When Picking an HNB Gear?

When nailing an HNB gear, hunt for stamps like CE (Europe’s health, safety, and green benchmarks), FCC (U.S. electromagnetic fit rules), and ROHS (hazardous stuff curbs). These stamps flag a nod to global safety rules. ChillMist ensures its goods hit these stamps via deep testing. This hands users trusty, safe picks.

How Does ChillMist Lock in Its Goods’ Trustiness?

ChillMist locks in good trustiness via tight caliber control rules. These span raw stuff checks, making process watch, and finished good sizing-up. The firm’s top-tier making tricks and nod to global benchmarks boost good trustiness further. Plus, ChillMist’s fresh streak shows in its use of cutting-edge tech—like optimized energy management setups that trim energy use while maxing battery life.